The Polyonics® family of ESD-Safe polyimide and polyester label materials are designed to help protect your most sensitive devices from electrostatic charges arising from both human contact (HBM) and charged devices (CDM). They provide durable static dissipative top surfaces and feature low charging pressure sensitive adhesives (PSA) and liners that generate less than 125 volts with liner removal and again when removed and repositioned.

Polyonics has worked with leading ESD experts, consultants within the electronics community and S20.20, 61340 and JED625B standards committees to develop a comprehensive white paper. The paper defines the ESD problem, describes the test standards, and offers guidance on how to best reduce ESD risks associated with using process required insulators around static sensitive devices.

To learn more about our unique engineered label and tape materials, call our technical experts at (603) 352-1415 or complete the form below to request more information. We look forward to working with you and earning your business.

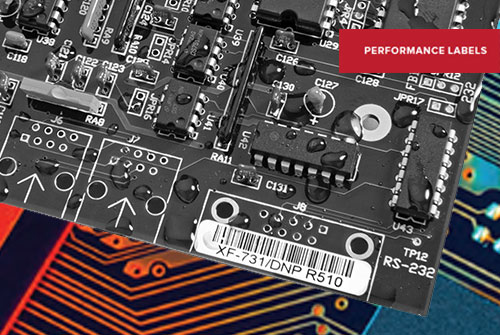

Visit our Performance Labels Library to learn more about our ESD labels and download product Data Sheets

Polyonics is proud to be associated with or be a member of the following industry organizations